Mousetrap Car Plans: Speed-Trap Racer

Earth shattering secrets for building record setting and winning mousetrap cars and racers. Here you will find all the latest and greatest untold construction secrets so you can build your very own mousetrap vehicle.

The Speed-Trap Racer is the fastest mousetrap powered racer anywhere and was designed after Doc Fizzix's own record-setting mousetrap racer that traveled 5 meters in 1.2 seconds. The Speed-Trap Racer is geared to generate a tremendous amount of torque while maximizing the transfer of potential energy into kinetic energy over a 5-meter distance. The Speed-Trap Racer is an easy-to-build top performing mousetrap racer that is designed for all high torque contests such as top-speed and King of the Hill. The Speed-Trap Racer comes ready-to-assemble with pre-cut and pre-drilled parts so you can be ready for action and racing on the same day. As with all our kits, The Speed-Trap Racer Kit comes with step-by-step instructions that are filled with tons of top secret performance tips and tricks that have been developed exclusively by Doc Fizzix so that you will have all the information you need to make The Speed-Trap Racer Kit a winner.

snappy: you will find everything you need inside your Speed-trap racer kit to build your very own mousetrap racer. The Speed-trap racer can be ordered from the comfort of your own home through the Doc Fizzix website where it will be shipped directly to your door step.

Attaching the Lever Arm (option #1)

Make sure you understand your contest regulations before you cut the mouse trap. If the contest states that you cannot cut and/or alter the mouse trap then you will need to skip this step and go to Attaching the Leer Arm (option #2). If the contest regulation allow for the mousetrap to be modified to extend the mouse trap's snapper arm then follow the steps listed bellow in order to prepare the mouse trap.

Looking at the mouse trap and take note of where the mouse trap's spring presses on the mouse trap's snapper arm. Using a pair of needle-nose pliers or a wire cutter, cut the snapper arm just before the corner bend on the side of the snapper where the spring is pressing down. Remove and discard the cut section.

step #1: Cut the mouse trap's snapper arm just bellow the corner on the side of the snapper that has the spring pressing down on it as pictured and removed the cut piece.

step #2: Using your needle-nose pliers, pry up on the "U" hook that is pressed into the mouse trap's base in order to remove the locking bar. Discard the "U" hook but save the locking bar for the next step.

step #3: Using your needle-nose pliers straighten the bent end (the non-loop end) of the locking bar.

step #4: Insert the locking bar all the way into one end of the lever arm. Only the locking bar's loop should be all that is sticking out of the lever arm; this will be where the string will be attached. You can glue the locking bar in place or for a better solution a small bend can be placed in the middle of locking bar so that the bar is held in place by it's own pressure, see image.

step #5: Slide the other end of the lever arm over the cut section of the snapper arm. Press the lever all the way down the snapper arm making sure the lever arm goes under the mouse trap's spring as pictured.

Attaching the Lever Arm (option #2)

Some contest rules state that the mouse trap can not be altered from it's original working condition. In this method a lever arm is attached to the side of the mouse trap's snapper arm without cutting the snapper itself so the mouse trap can still be set in the traditional method. This method can be used to secure a longer lever arm to the mouse trap's snapper without having to cut the snapper.

step #1: Attach a lever arm to the side of the mouse trap's snapper using several pieces of picture wire or three small zip-ties as pictured.

step #2: Trim any left over wire/tip-zie and then place a small amount of super glue on the wire/zip-ties to secure them in place and to the snapper arm.

Making The Frame

Use the following steps to assemble the frame.

frame: this is the finished example of the frame we are building.

step #1: glue the side rails to the bottom of the mouse trap. Take note of the orientation of the mouse trap and the side rails from the picture. The front of the side rail has the small axle hole or the slit and this is glued to the front of the mouse trap.

step #2: inspect the axle holes to make sure they are clear of debris, us a file or some sand paper to clean any debris if necessary.

Inspect the axle holes on the frame to make sure they are clear of debris. If necessary, clean up the axle holes using a small round file or roll-up some sandpaper and lightly clean the edge of the axle hole to make sure the axle holes are clean of any debris. Be careful not to enlarge the diameter of the axle hole by filing or sanding any material away, only clean the edge of the holes.

Adding the Rear Wheels

The kits comes with four metal washers, two are used as bushings to decrease the bearing friction and the other set as thrust washers to decrease the side friction. Start by gluing one set of washers to the frame making sure to center the washers over the pre-drilled axle holes.

step #1: center and glue a washers over each of the rear axle holes. Take care to make sure the washers are lined up over the pre-drilled rear axle holes. It might be easier to use a slow drying white or wood glue instead of a super glue. A slow drying glue will give you more time to adjust the washers if needed.

step #2: once the washers are dry, make sure there is no glue residue on the bearing surface, clean with a small file or sandpaper.

step #3: Place the rear axle through one of the ultra-sticky foam wheels.

step #4: place a small amount of glue (super glue) around the wheel and axle joint, turn the axle within the wheel just to help spread the glue.

step #5: When the glue is dry, place a washer on the axle and insert the assembly through the axle holes in the frame.

step #7: place another washer on the other end of the axle.

step #8: Finally, attach the other foam wheel to the other end of the axle, make sure to super glue the axle to the wheel so that it does not slip.

bonus tip: Place some graphite powder in the axle holes and spin the wheels, this will work the graphite powder into the wood and reduce the friction.

Attach the Front Wheels

The front wheels are made of a super lightweight plastic in order to decrease the rotational inertia so that more of the mouse trap's energy can be used to accelerate the vehicle.

step #1: place the small axle into the precut slits on the bottom of the side rails.

step #2: place one of the plastic wheels on each side of the small axle.

step #3: using a needle-nosed pliers, bend the end of the wire slightly so that the plastic wheel will not fall off.

step #4: the axle can be bent slightly as needed in order to correct any steering issues.

Attach the Axle Hook

The important part of a winning mousetrap project is Doc Fizzix's "easy-to-wind" and "snag-free " string release system that will not tangle or snag.

step #1: A small zip-tie is positioned in the center of the drive axle and locked in place.

step #2: The zip-tie is trimmed and cut so that the excess tail of the zip-tie. Make sure to trim the excess zip-tie tail as close as possible to the locking hub.

step #3: Super glue the zip-tie to the axle to make sure the zip-tie axle hook does not slip when under tension.

step #4: Catch the zip-tie axle hook with the string loop and wind the string as normal.

How to Make a Loop Knot

It is important for the pulling string to have a correctly tied loop knot in order for the Doc Fizzix "easy-to-wind" and "snag-free " string release system to work properly or the mousetrap vehicle will come to an instant stop. Learning how to tie knots brings me back to my Boy Scout days but is also an extremely important part of building a successful mousetrap car.

Try to carefully study the images on how to tie a loop knot as seen bellow. Please note that the string being used if ONLY for illustrating how to tie the correct knot, it is NOT recommended to use a thick string with mousetrap vehicles. Also, the loop knot should be large enough so that it releases from the drive axle without snagging on the axle hook (see images).

step #1: Fold the string over.

step #2: Tie a traditional knot using the folded part of the string as pictured

step #3: the finished product.

Attaching the String

The string is tied to the tip of the lever arm and then adjusted so that it "just" reaches the drive axle

step #1: Tie the string to the lever tip of the lever arm

step #2: Pull the string towards the drive axle

step #3: tie a loop knot in the string so that the string is "just" long enough to reach the drive axle.

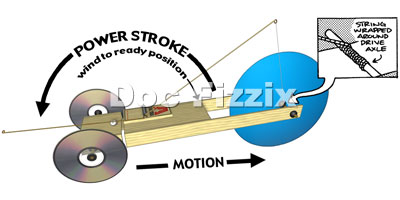

Winding The String

When winding the string around the drive axle make sure NOT to put any slack in the string. The string should be wound tight as it winds around the drive axle or the mousetrap racer may have a jerky motion as the string unwinds. Always wind the string using the full load of the mouse trap, do not help lift the lever arm during the winding process (except maybe at the start of the wind and then only just to get things going.

bonus tip: Never put slack in the string as you wind it around the drive axle. Always wind the string under tension.

bonus tip: some times it is necessary to lift the lever arm in order to start winding the string but then put the string back under tension to make sure the string winds under the force of the mouse trap's spring.

Winding The String

When winding the string around the drive axle make sure NOT to put any slack in the string. The string should be wound tight as it winds around the drive axle or the mousetrap racer may have a jerky motion as the string unwinds. Always wind the string using the full load of the mouse trap, do not help lift the lever arm during the winding process (except maybe at the start of the wind and then only just to get things going.

bonus tip: Never put slack in the string as you wind it around the drive axle. Always wind the string under tension.

bonus tip: some times it is necessary to lift the lever arm in order to start winding the string but then put the string back under tension to make sure the string winds under the force of the mouse trap's spring.

Setting the Gearing (advanced option)

Although your speed-trap racer will work well straight from the kit you may want to go for a new record. In order to improve the speed-trap racer's performance you will need to adjust the gearing of the drive wheel and the drive axle. Since the size of the wheel is set, the only adjustment that can be made is to the size of the drive axle. The objective is to increase the size of the drive axle by winding tape around the axle. You will need to test the vehicle over-and-over again in order to achieve the maximum acceleration possible before the drive wheels spin out. For each wrap of tape around the drive axle you will increase the vehicles acceleration, to much tape and the vehicle tires will spin out at the start. Try to find the exact amount of tape needed for maximum acceleration just before the racer's wheel begin to slip.

step #1: Starting in the center of the axle and carefully wind tape around the axle to build up the axle diameter.

step #2: Reattach the axle hook and then test the mousetrap racer. If more torque is still need after testing then add more tape as described above.

bonus tip: layers of tape can be removed to make a series of gears or a transmission on the axle so as to change the pulling force in steps.

*Can't find what you're looking for? Ask Doc Fizzix »