Mouse Trap Cars: Decreasing Friction

Controlling friction is your number one goal to building a winning and record-setting mousetrap powered vehicle. Learn how to decrease and eliminate friction.

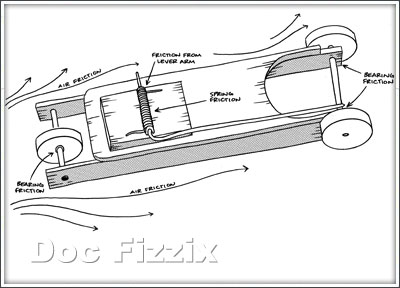

Friction is a force that acts against the motion of all moving objects. We cannot totally eliminate friction but we can try to reduce it as much as possible. As a general rule of thumb, the more moving parts a device has the greater the force of friction acting against the system. The first step in deceasing friction happens in the planning and the designing of your mousetrap vehicle. As you design your project think about the points of friction that you will have and look for ways to decrease the friction at these points. Because the number of moving components increases the friction point look for ways to simplify the design as much as possible. Using a lot of gears and pulleys may be a great way to change the pulling force and the pulling distance but this will also lead to more points of friction that will have act against your vehicle's motion, look for simplicity.

identify friction: friction is the force that acts against the motion of every moving object. Study your vehicle to identify points of friction and where friction can be controlled.

Axle Points

The number one point of friction on any mousetrap car is where the axle system comes in contact with the frame of the vehicle. In most cases an axle will be in direct contact with the frame and there is a lot that can be done to decrease the friction at this contact point.

Friction at the axle points depends on:

- The diameter of the axle

- The pressure on the axle by the bearing

- The types of materials used for the axle and bearing

Axle Diameter

Larger diameter axles have greater friction at the bearing point when compared to a smaller diameter axle. With a smaller diameter axle the force of friction is applied closer to the center of rotation and has less bite or less effect on the axle's state of rotation than with a larger diameter axle. Try to select axles that are equal to or less than 3/16 inch in diameter.

Bearing Pressure

Bearing pressure is a combination of how much a bearing is pressing on and/or pinching on an axle and is partly determined by the weight of the vehicle's chassis pushing down on the bearing points. Lighter mousetrap cars will have less weight pushing down on the bearings so always select lightweight building materials when constructing your mousetrap vehicle. Also make sure that your vehicle's bushings do not pinch on the axle, try to have a small amount of play between any axle and it's bushing system.

Materials

Some materials have more friction when used together than other materials. The friction at a bearing point will depend on the materials you select for the axle and the bushing. There are many different materials that you can match-up when making a bushing system but some times it is best to have a chart of coefficients of friction in order to help determine which of the materials that are available to use will work the best together. See bellow

Graphite powder

A small amount of graphite powder can be applied to any two surfaces that rub against one another to decrease the friction.

Important: NEVER use graphite powder with ball bearings, ball bearings are already designed to reduce friction and the graphite powder will damage the bearing.

how to apply: Graphite powder can applied to the contact point between the axle and the frame. As the graphite is applied the axle/wheels are spun to work the graphite into the frame, repeat as needed.

bonus tip: Graphite powder can also be applied to the mouse trap's spring to even reduce any friction caused by the spring rubbing on its self.

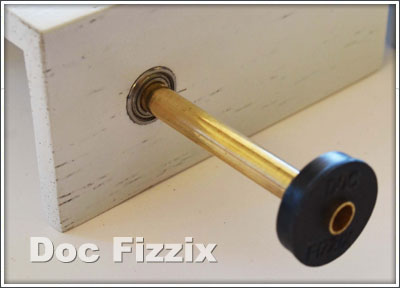

Bushings

Bushings are used to reduce the surface friction at an axle point. The idea with a bushing system is to match-up materials that have the less friction when used together. For example, brass rubbing on wood has more friction than brass rubbing on steel. In this example, if the brass axle can be made to rub on a steel bushing as apposed to the wood then the total friction of the axle will be reduced and performance of the mousetrap vehicle will be improved. There are many different materials that you can match-up when making a bushing system but some times it is best to have a chart of coefficients of friction in order to help determine which of the materials that are available to use will work the best together. From the table bellow you will see a common list of materials and their coefficient when combined together. The idea here is that the smaller the number the less friction two materials have when used together. Use this table as your guide to help pick the best materials to help reduce friction with your bushing system.

bonus tip: Bushings can be cut from brass or other tubing.

bonus tip: Placed bushing into a hole in the frame. Use graphite powder to help reduce the surface friction.

bonus tip: Bushings can be cut from plastic straws and placed into a hole in the frame.

bonus tip: Metal washers make great bushings. Metal washers can be glued directly to the frame to hold the axle. Use graphite powder to help reduce the surface friction.

Teflon Bushings

If available, Teflon is one of the best bushing materials you can use. Sometimes you can find Teflon washers at a local hardware store. There are many different materials you can choose from to use with a bushing system but some times it is best to have a chart of coefficients to help determine what materials will work the best when used together. From the table bellow you will see a common list of materials and their coefficient when combined together. The idea here is that the smaller the number the less friction two materials have when used together. Use this table as your guide to help pick the best materials to help reduce friction with your bushing system.

Ball Bearings

Because nothing rolls like a ball, use micro-ball bearings! Micro Ball Bearings are designed to replace energy wasting bushing systems with a more efficient ball-bearing that will reduce the total friction by as much as 50-100%; this means your vehicle will travel up to 50-100% further and faster than a similar racer using a bushing system. Micro-ball bearing also decrease the normal wear that occurs between moving parts and helps eliminate heat build-up so your mousetrap vehicle can use more of it's starting energy for increased performance. Micro bearings take a little more work to set-up and are intended only for those individuals who want to decrease friction to the max. Micro-bearings can be used with all rubber band and mousetrap racers to reduce friction.

how they work: Micro-ball bearings hold the axle and allow the axle to spin on a surface of tinny balls that reduce the surface friction to near zero.

how they work: Micro-ball bearings are mounted into the frame of the vehicle and prevent the axle from touching the frame. Instead of the axle rubbing on the frame as with a bushing system.

bonus tip: To improve the performance of ball bearings soak the bearings in WD-40 in order to remove the pre-packed grease. Most ball bearings come pre-greased and are designed for fast moving RC cars. With slow moving or lightweight mousetrap racers the pre-packed grease adds way to much friction and must be removed. It is best to soak the bearings and then spin them on the end of a pencil to help get all the grease out. To even go one step further, you can try to remove the casing on the bearing itself and this will make it easier to flush out the grease and will also reduce the friction even more.

Thrust Bearings

One common mistake is putting spacers to close or to tight to the frame, there should always be a small amount of side-to-side play so that wheels and/or axle spacers are not pinching against the frame creating a lot of extra friction. Try to have a minimum gap of 1/8 inch between the frame and any spacers (or wheels) in order to decrease any rubbing friction. Use thrust washers and graphite powder between spacers (or wheels) and the frame to help reduce the rubbing friction.

how they work: thrust bearings are placed between the wheels and the frame to decrease the rubbing friction.

*Can't find what you’re looking for? Ask Doc Fizzix »